In the April issue we started at the front end; this month it is all about the installation of the rear bogie.

https://nztrucking.co.nz/mini-big-rigs-front-suspension-installation

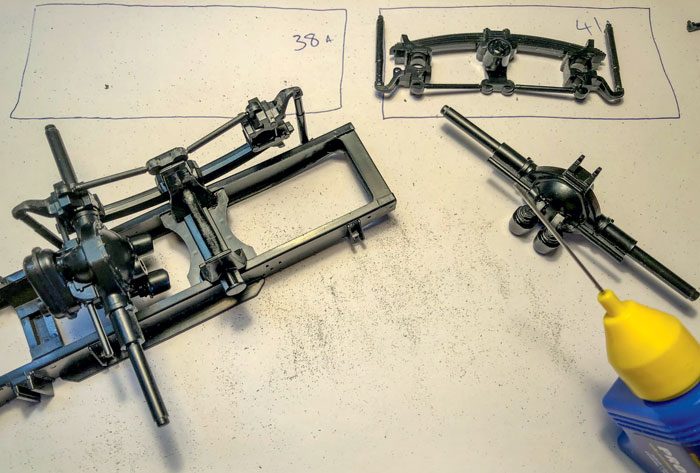

Photo: By gluing parts 38A and 39A into place first, you will find that it will greatly simplify the installation of the other rear bogie components.

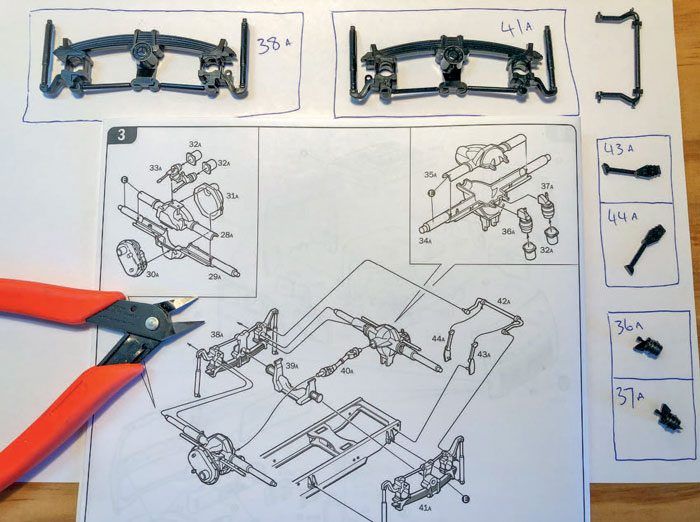

We tackle step 3 of the instruction sheet this month and complete the installation of the rear bogie and suspension assemblies. As we have learnt in the first two steps of the assembly process, we start by identifying all the required parts as detailed on the instruction sheet and carefully remove them from the sprue. Step 3 again has two preassembly stages to complete before fitting items to the chassis: the construction of both the front and rear differentials. Again, as with the front-end last month, I would suggest laying the various parts out on a blank piece of paper with their identification numbers written beside them; this avoids any confusion when assembling. You will find many moulding seams with these larger parts like the diff heads, axles and spring packs, so again, using your file and fine-grit sandpaper, work these away to an acceptable level. This is advisable, as being a tractor unit you will see them when painted and complete.

Photo: Identifying the required parts and laying them out on a sheet of paper with their reference numbers penned beside them will save you from confusion when assembling.

Once the assembled diffs have had a chance to dry, we can proceed with attaching the components to the chassis. The instructions display all the major parts coming together in one movement; the reality is attempting this proposed procedure would end in a gluey mess stuck to the ends of your fingers. The way forward here is a more controlled sequence that will save a lot of frustration. First I would suggest placing and gluing parts 39A, the central trunnion, and part 38A, the left-hand side spring pack assembly, to the chassis. Before parts 39A and 38A completely dry and set in place, dry-fit (do not apply glue as yet) the two pre-assembled diffs into the housings on 38A. Now introduce 41A, the right-hand side spring pack, into place. You will find that it will fit with an audible click as the shock absorbers lock into the locating points on the side of the chassis. At this time you can slide part 40A, the rear drive shaft, into place between the two diff heads.

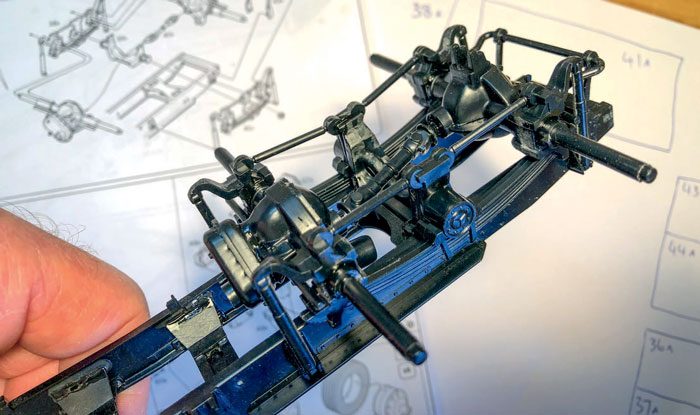

Photo: With the balance of components in place you will find that the rear bogie assembly holds itself together while you introduce glue to the connection points between the various parts.

Once you are happy with the fit of these parts you can then easily apply glue to all the contact locations and allow to dry. This way you have more time to ensure that these components are seated 100% correctly; this is very important, as you want the completed truck‘s wheels to all be making contact with the ground. With the rear bogie now fitted and fixed in place it is an easy step to fit the last three parts (42A, 43A and 44A) – the rear sway bar and support brackets. We now have a chassis complete with front and rear running gear that is nearly ready to roll. Next we construct the mighty V8 and transmission assembly, as well as complete fitting the chassis accessories in readiness for a coat of paint.

Photo: Our subject matter, Pilkington Automotive Glass/Ken Kirk circa 1992.